Metal-printed 3D components with complex geometries and tight tolerances and at the same time manufactured with the highest precision for demanding industries such as medical technology, the electronic sector or jewelry industry? Of course, with Incus and Schinko, this is absolutely possible.

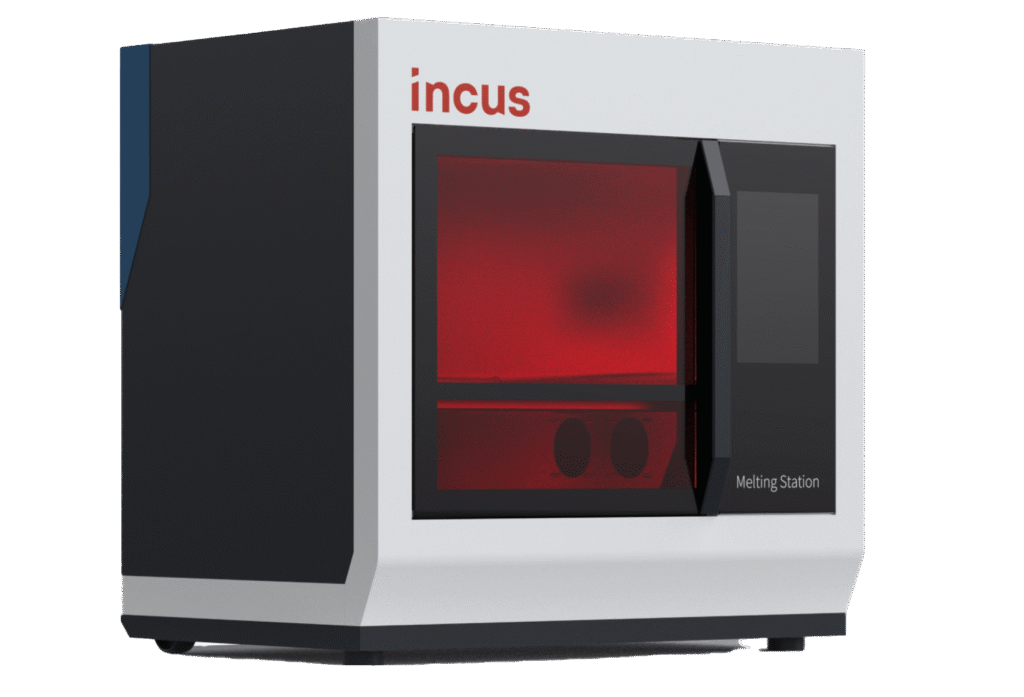

Lithography-based metal manufacturing (LMM) technology combines the precision of photopolymer lithography with the unbeatable features of metals. Metal powder is embedded in photoreactive binder and the desired component is built up layer by layer using photopolymerisation. The resulting green parts must then be freed from the surrounding material so that it can be sintered. This is where Schinko comes in. Schinko and Incus have developed the Melting Station for this post-process in additive manufacturing, where the polymer binder is removed.

Schinko was already on board during the development of the Incus 3D printers Hammer Pro and Hammer Evo, and their housing production also takes place in Neumarkt. In collaboration with industrial designer Michael Golser, a sophisticated modification for the Melting Station has now been created based on the 3D printer designs, which fits perfectly into the product family. It is sophisticated because maximum material quality had to be achieved at optimised costs. Schinko was responsible for essential mechanical engineering work on the Melting Station. Development took place in close cooperation with Incus, and series production is now also carried out by Schinko.

Manuel Grubhofer,

Head of R&D Engineering at Incus GmbH

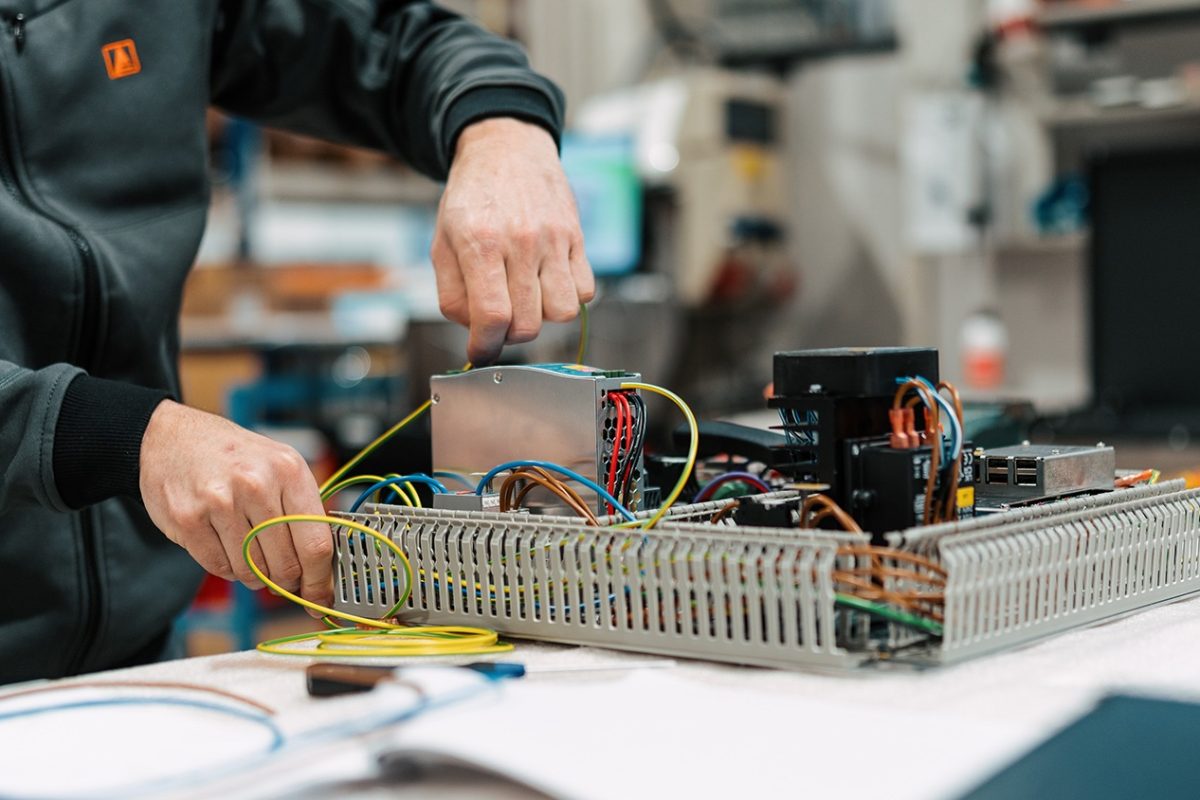

The melting station consists of two chambers: the melting chamber, where the feedstock is melted, and a cooling chamber for the collected material. The melting zone is heated to the required temperature using a heating element and appropriate air circulation, while the collection chamber is kept at room temperature to protect the material so that the melted material can be reused. This also ensures a sustainable and economical process. Schinko also took care of the software installation and the final testing of the heating, ventilation and lighting systems. The Melting Station is assembled by Schinko’s newly formed systems engineering and mechatronics assembly team.

Manuel Grubhofer,

Head of R&D Engineering at Incus GmbH

Not only bathtubs, washbasins, etc. or aircraft cabin interiors are made from the innovative mineral material Corian® due to its particularly good hygienic properties, but also the interior of the Incus Melting Station. Its non-porous surface makes it particularly easy to clean, and valuable metals such as gold can be separated without any loss or impurities – ideal conditions for the Melting Station when used in medical technology, jewellery production or other precision industries. Schinko’s expertise in materials, combining over 30 years of experience in metal processing for stable, resistant and durable machine architectures with innovative materials that meet the desired appearance, hygiene and other requirements, has once again proven its worth in this project.

Micheal Schröcker,

Head of Sales & Development at Schinko